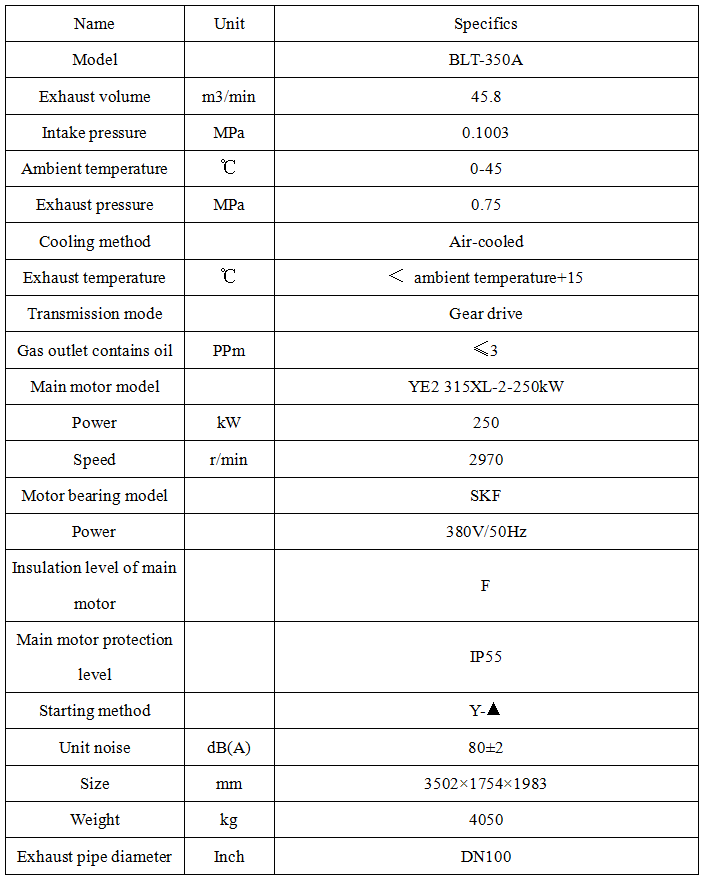

BLT-350A/250KW

Technology source1. The first-class Atlas host with the world's core technology:High quality core hosts determine the operating life and economic cost of the entire machine.Atlas host, the most advanced SAP model line.144 years of research and development experience and professional skills in ma

BLT-350A/250KW

Details

Technology source

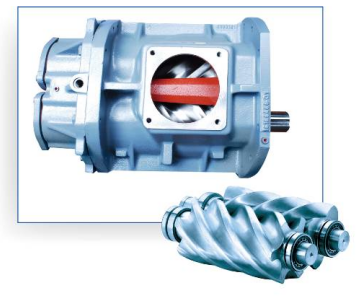

1. The first-class Atlas host with the world's core technology:

High quality core hosts determine the operating life and economic cost of the entire machine.

Atlas host, the most advanced SAP model line.

144 years of research and development experience and professional skills in manufacturing hosts.

The rotor material is 40Cr, ensuring rigidity.

The highest compression efficiency compared to the previous year.

Vibration below 3mm/S, noise below 75 decibels.

Equipped with SKF high-precision bearings, ensuring even meshing clearance.

Factory dynamic and static balance testing.

Atlas patented SAP profile, with equal rotor diameter; Compared to the combination of 5/6 teeth or 4/5 teeth, the female rotor has higher stiffness; The main engine value of screw air compressors accounts for 30-40% of the entire machine, so understanding and selecting the main engine is important for both supply and demand sides.

BLT air compressor adopts Atlas host and has advanced SAP screw tooth type patented by Atlas Copco Group, which effectively extends the life of moving parts.

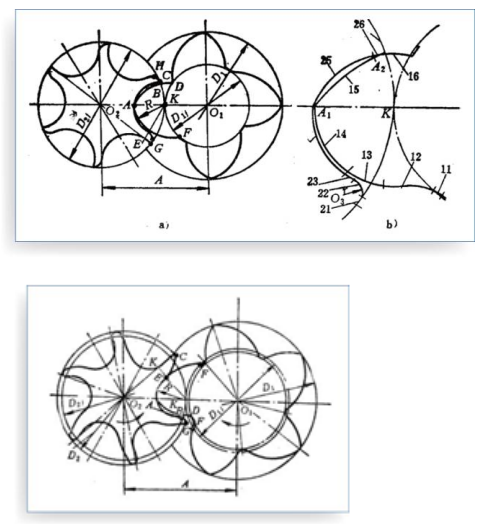

2. The unique characteristics of globally recognized advanced production lines (SAP production lines):

4/6 tooth combination with equal rotor diameter

Using 40cr material to further enhance the stiffness of the rotor

The tangent line of the tooth edge is located in the same horizontal plane

The resulting effect is:

1. The design fully considers the compression force and contacts the trailing edge of the tooth side.

The gap between the rotor sealing lines has been minimized through repeated experiments.

3. No knocking or noise.

4. The exhaust end has the smallest air outlet (small leakage triangle).

5. Minimize internal leakage and losses.

6. Higher internal pressure ratio (10 bar).

7. Obtain a larger rotor diameter to further improve efficiency.

8. The tip speed is low and close to the optimal speed.

9. The tip speed is low and close to the optimal speed.

B. Comparison of tooth profile structure between SAP profile and other profiles

1. Sigma line (used by Kaeser) GHH line (used by most assembly plants in China and Asia Pacific region):

Uneven force distribution on 5/6 teeth results in excessive vibration, noise, and wear.

The diameter of the rotor is small, which cannot achieve optimal efficiency, and the leakage triangle increases with the passage of time.

2. X-shaped line

The profile line used by the group company, with a smaller rotor, has been mostly replaced by SAP.

C. Comparison of area utilization between SAP profile and other profiles:

Design principle: We hope to generate more displacement (working volume) during tooth movement

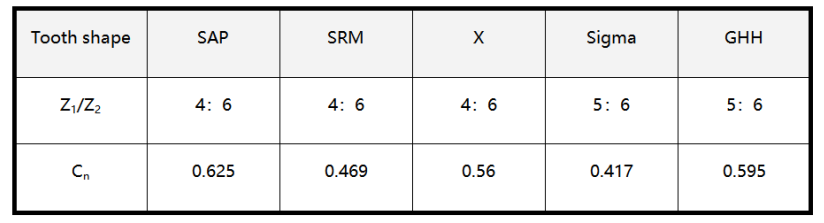

Table 1 Area utilization efficiency of several tooth profiles Cn=F/Dm

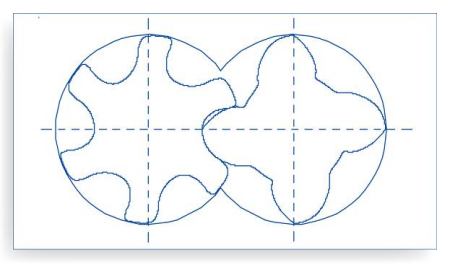

D. Comparison of weight factors between SAP profile and other profiles

Balance weight by increasing the diameter of the female rotor

Slight triangular changes in leakage after long-term use

Minimize the burden of the positive rotor on the bearing

The most common GHH lines in China and the Asia Pacific region

In order to achieve higher power performance, the female rotor is reduced in size

After two to three years of use, the tooth gap is prone to deformation

In addition to bearing the weight of the male rotor, the bearing also bears more reaction forces from different speeds of the female rotor

Conclusion: At present, the most efficient host lines are recognized in the world as "SAP lines of Atlas Copco Group", "CF lines of GHH Company" and "Sigma lines of Kaeser". These three types of rotor profiles have gradually evolved and improved through years of production and design experience.

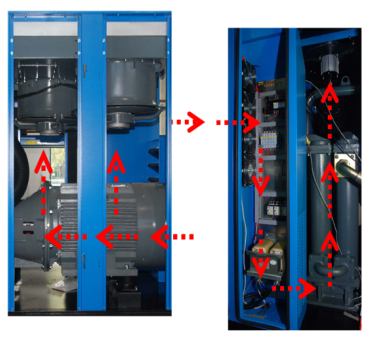

Integrated variable frequency compressor

-The frequency converter and air switch are installed in the electrical box of the air compressor

- Perfectly matched the motor, frequency converter, and variable frequency controller

- Fully tested before leaving the factory

Best energy-saving effect, high reliability, and convenient installation and use

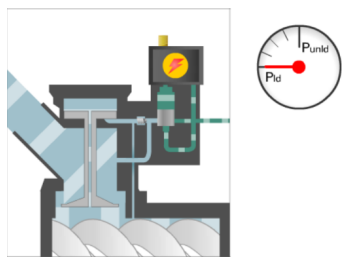

Integrated vacuum intake valve

- Lower pressure drop

- No large and heavy springs

- Simpler with fewer components

- Maintenance free

Vector controlled heavy-duty frequency converter

- Specially designed PID control algorithm

- Response time less than 20 ms

- Very smooth torque output curve

-Fast response, high accuracy, and wide adjustment range

-Equipped with motor short circuit detection function

Electromagnetic compatibility

- A comprehensive circuit system design ensures that the frequency converter can meet electromagnetic compatibility standards

- Don't worry about the high-frequency harmonics generated by the frequency converter affecting other electrical appliances

Air compressor cooling system

-Has excellent high-temperature stability; And good environmental adaptability

Compressor cooling channel, frequency converter dedicated cooling channel

Logic control of anti condensation cooling fan

According to the temperature of the environment, the computer controller automatically turns on the cooling fan only when it needs to be turned on, saving customers every penny of energy consumption.

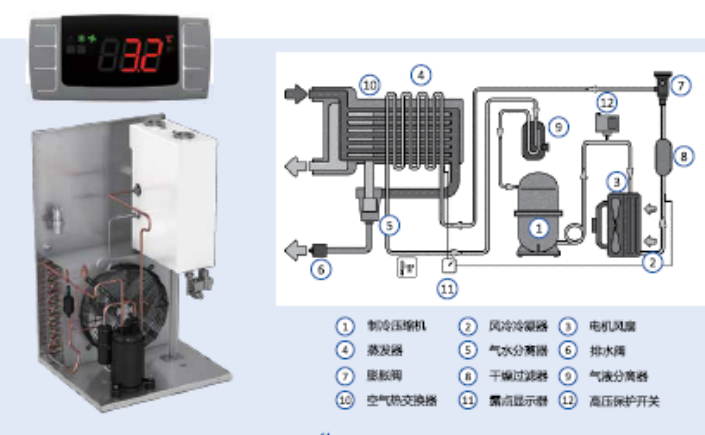

Characteristics of BLT BLD freeze dryer

Characteristics of BLT BLF Filter

Dust particles, oil, and moisture in compressed air can damage gas equipment and even contaminate the final product. In order to save your investment costs, Bolaite provides customers with complete post-processing solutions.

Performance advantages:

-Efficient cleaning ability, high filtration accuracy, and low pressure loss

- Imported filter material with stable performance and long service life

- Compact structure, easy to install and maintain

- With differential pressure indicator

- Optional zero loss, automatic drain valve

- Reduce system operating costs

Provide comprehensive compressed air quality assurance

Filtering accuracy&reference working conditions:

Imported multi-layer fiberglass filter cartridge with efficient cleaning ability, low pressure loss, and outstanding filtration effect

Both the inner and outer filter elements have undergone anti-corrosion treatment, ensuring stable performance and long service life

Compact structure, lightweight, easy to install and maintain

Provide comprehensive compressed air quality assurance to improve the reliability of compression systems

BLE system filters are equipped with standard differential pressure indicators and zero loss automatic drain valves

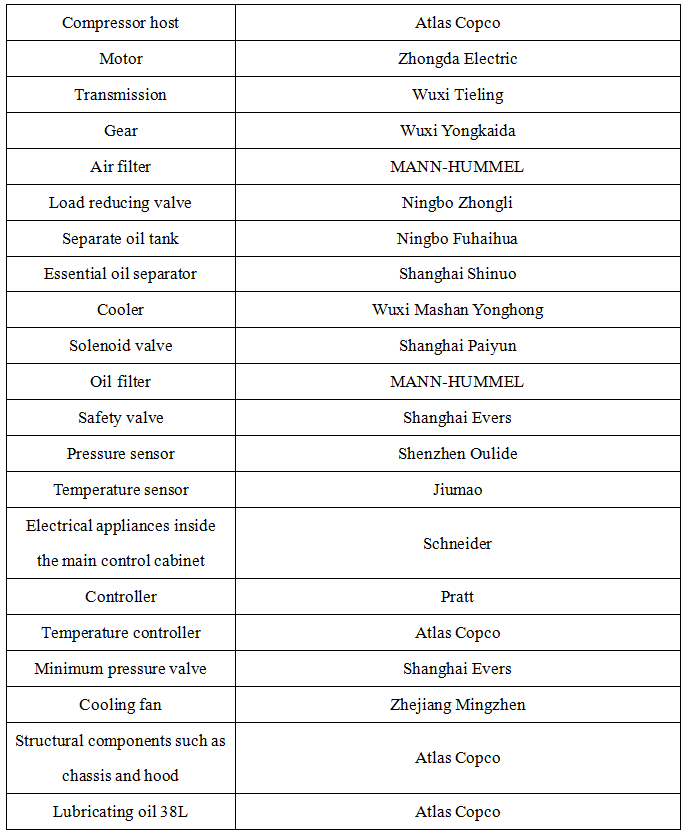

BLT-100AG Power Frequency Screw Air Compressor Configuration List

Flowchart Description

Process description: Twin screw air compressor → Air storage tank → Filter → Drying machine → Filter.

Air quality: pressure dew point: 2-10 ℃; Dust content: < 0.01 micrometers; Oil content: < 0.01ppm